Wave Spring Applications

Wave springs are widely used in the mechanical manufacturing industry, petroleum and chemical engineering, hydraulic equipment, automotive and locomotive manufacturing industry, aviation industry, refrigeration engineering, and other industries, such as motors, compressors, fluid valves, water valves, gas valves, automotive clutches, brakes, electrical connectors, bearing preload devices, compensation devices, shaft seals, and mechanical seals, etc.

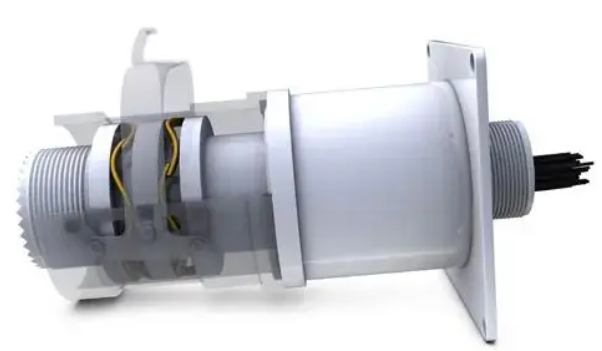

1、Electrical Connector For Aerospace

The two single-layer overlap wave springs in this device will apply a constant force to the connector when compressed, providing a guarantee for continuous connection.

2、Flow Valve

With the increase of fluid pressure, the multi-turn wave spring precisely controls the linear displacement of the plunger, positioning the fluid hole to allow proper fluid flow.

3、Pressure Relief Valve

The exact pressure is achieved using the wave spring. The air pressure under this device will increase the spring load, forcing the plate away from the sealing surface, thus providing a pressure relief mechanism. When the load applied to the spring decreases, the device can be sealed again.

4、Water Valve

The wave spring, also known as a flat wire compression spring, maintains a constant load and engages with the threads on the spindle to prevent the valve handle from rotating. When the handle is rotated counterclockwise, the resistance of the wave spring increases, reducing the likelihood of continued rotation.

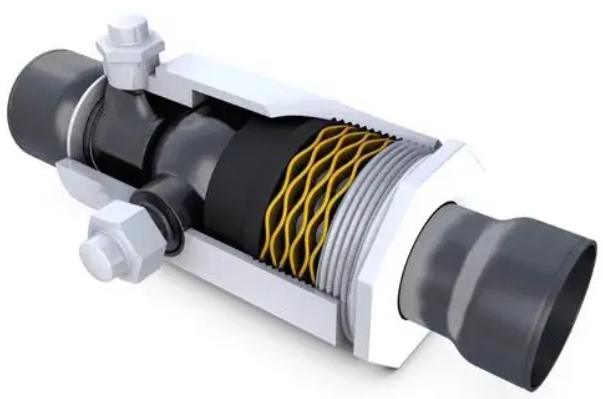

5、Face Seal

Wave springs apply pressure to accurately apply a load to the carbon steel surface based on the mating surface, thus properly sealing the liquid. Wave springs operate within a fixed working range and provide precise force. Wave springs replace stamped wave gaskets that cannot maintain the necessary elastic ratio. It is necessary to apply precise pressure from the carbon steel surface to the sealing surface provided by the wave spring to avoid excessive wear while maintaining proper sealing.